Categories

Contact Us

E-mail:

service@wanxinpipe.com

WhatsApp:

+8617370959999

Tel/WeChat:

+8617370959999

Address:

No. 219 Renkai Road, Renqiu Economic Development Zone, Cangzhou City, Hebei Province, China

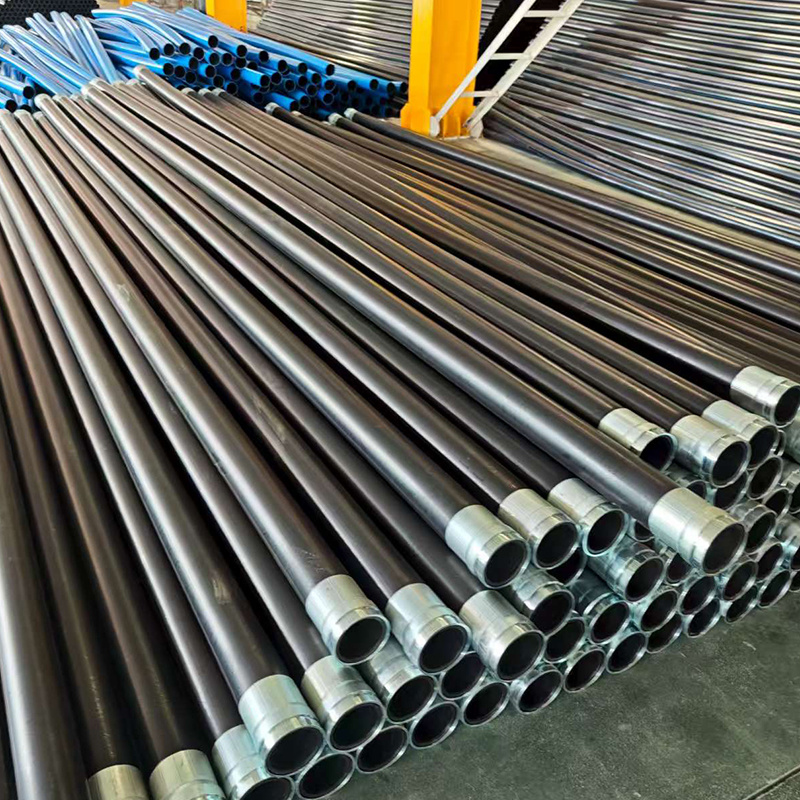

Mining steel wire mesh skeleton polyethylene (PE) composite pipe

- Product Detail

-

Physical and mechanical properties

Application Symbol Test Temperature Short-term Hydrostatic Pressure & Burst Pressure Test Time (h) Performance Requirements SSPE-KML 20℃ Nominal Pressure × 2 1 No rupture, no leakage 80℃ Nominal Pressure × 2 × 0.6 No rupture, no leakage 20℃ Burst Pressure ≥ Nominal Pressure × 3 Burst SSPE-KMQ 20℃ Nominal Pressure × 1.6 × 2 1 No rupture, no leakage 80℃ Nominal Pressure × 1.6 × 2 × 0.6 No rupture, no leakage 20℃ Burst Pressure ≥ Nominal Pressure × 3.3 × 1.6 Burst Performance characteristics

1. Strong corrosion resistance and long service life. Pipe materials have strong corrosion resistance, with a service life 4-6 times that of steel pipes, and overcome the phenomenon of thin pipe walls and shortened service life caused by corrosion and wear of steel pipes.

2. High security performance. Both the inner and outer layers are made of anti-static and flame-retardant modified polyethylene, and their anti-static and flame-retardant properties can meet the AQ1071-2009MT181-88 standard and on-site requirements.

3. Good impact resistance and flexibility

4. Smooth pipe wall with low resistance.

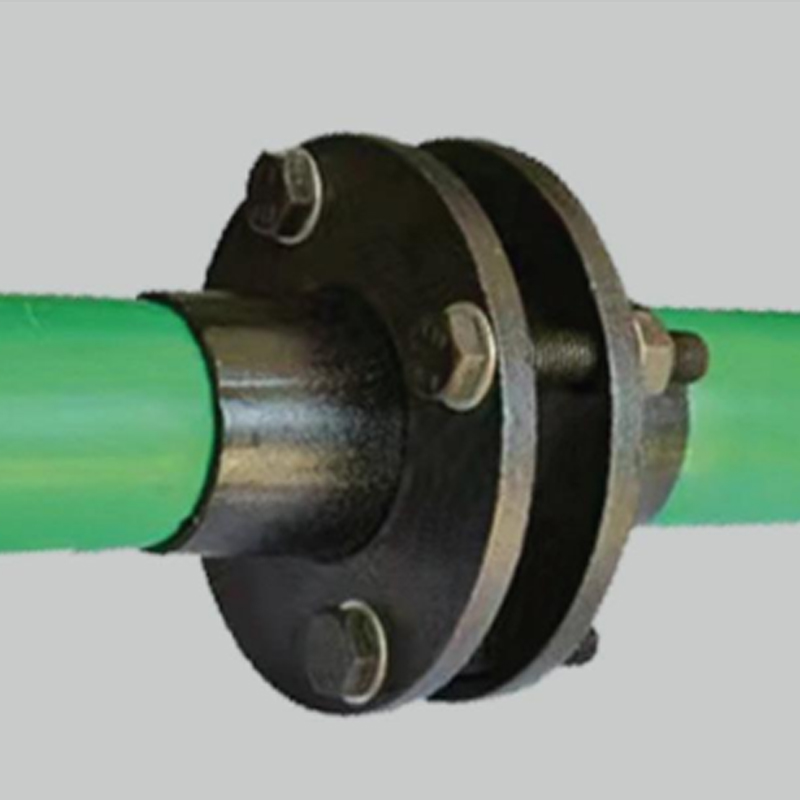

5. The connection method is secure and reliable

6. Lightweight, easy to transport and construct.

7. Green and environmentally friendly. The raw material is PE resin. Clean, non-toxic, does not produce secondary pollution, and can be reusedTechnical Parameter

No. Item Performance and Parameters 1 Appearance Clean and smooth inner/outer surfaces, free from bubbles, cracks, obvious scratches, dents, impurities, or uneven coloring 2 Cross-section Perpendicularity Pipe ends cut square to axis with perpendicularity within ±5° 3 Wall Thickness Deviation Deviation within limits shown in Tables 2 & 3 4 Wall Thickness Minimum thickness meets Tables 2 & 3 requirements 5 Nominal OD Deviation Complies with Tables 2 & 3 requirements 6 Compression Stability No cracks/damage when compressed to 50% of nominal OD 7 Peel Test Peel strength ≥100N/cm 8 Groove Test 9 out of 10 samples show no cracks/damage 9 Hydraulic Test (1) At 20°C, withstands 2.4×nominal pressure for t/h without leakage/damage

(2) At 20°C, withstands 5.28×nominal pressure for 1min without leakage/damage10 Surface Resistance Water supply/drainage pipes: ≤1.0×10⁴Ω (avg)

Gas extraction pipes: ≤1.0×10⁴Ω (avg)

Ventilation pipes (negative/positive pressure): ≤1.0×10⁴Ω (avg)

Shotcrete pipes: ≤1.0×10⁴Ω (avg)

Universal pipes: ≤1.0×10⁴Ω (avg)11 Alcohol Lamp Test (1) 6 samples: avg flame time ≤35s (single ≤105s)

(2) 6 samples: avg afterglow time ≤205s (single ≤605s)12 Negative Pressure Test Withstands 0.097MPa for 100h without collapse/damage Mining pipe fittings

Groove type flexible low-voltage pipe clamp Groove type flexible high-pressure pipe clamp Trench tee KRJ shoulder type pipe clamp

Remote liquid supply ultra-high pressure pipe clamp Groove bend CDU circular pipe clamp KRH short-circuit pipe clamp

Groove type flexible high-pressure pipe clamp Remote liquid supply ultra-high pressure pipe clamp Reducer joint External locking sleeve flange

External locking coupling Internal locking flange Flanged flange Embedded split flange Pipe production line

Test equipment

Workshop

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!